What specific type of blade steel do you prefer for a men’s everyday carry pocket knife, and why?

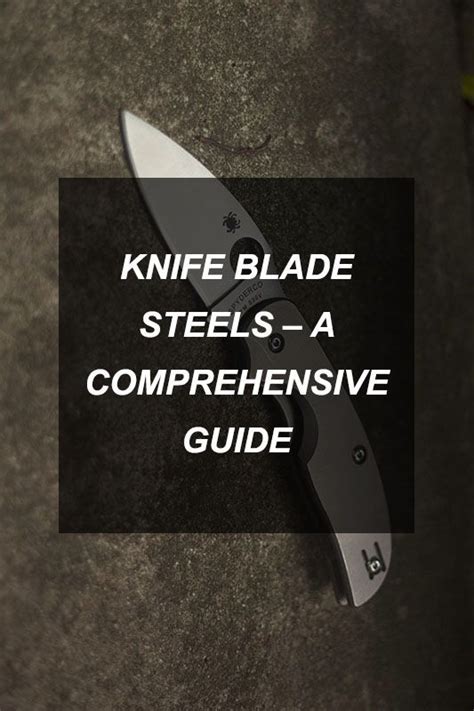

The Unsung Hero: Why Blade Steel Matters for Your EDC Knife

For many men, an everyday carry (EDC) pocket knife is far more than a tool; it’s a reliable companion for countless tasks, from opening packages to emergency situations. While handle ergonomics and locking mechanisms are important, the heart of any good knife lies in its blade steel. The steel dictates the knife’s performance across critical metrics, influencing how well it holds an edge, resists rust, and withstands abuse. Choosing the right steel can dramatically elevate your EDC experience, while a poor choice can lead to frustration.

The Four Pillars of Blade Performance

When evaluating blade steel, four primary characteristics come into play, often in a delicate balance:

- Edge Retention: How long the blade stays sharp under use. This is crucial for consistent performance without frequent sharpening.

- Toughness: The ability of the steel to resist chipping or breaking under impact or lateral stress. A tough blade can take a beating without fracturing.

- Corrosion Resistance: The steel’s ability to resist rust and staining, particularly important for knives exposed to moisture, sweat, or acidic materials.

- Ease of Sharpening: How difficult it is to restore a keen edge. Steels with high edge retention are often harder to sharpen.

No single steel excels perfectly in all four areas; improvements in one often come at the expense of another. The ideal EDC steel is therefore a thoughtful compromise based on anticipated use.

My Preferred EDC Blade Steel: CPM-S35VN

For a men’s everyday carry pocket knife, my strong preference leans towards CPM-S35VN. This powdered metallurgy stainless steel offers an outstanding balance of properties that are highly desirable for daily use, making it a true workhorse in the EDC world.

Why S35VN Stands Out

- Excellent Edge Retention: S35VN holds a working edge for an impressive amount of time, reducing the need for constant resharpening. This means more time using your knife and less time maintaining it.

- Good Toughness: While not as tough as some tool steels, S35VN is remarkably chip-resistant for a stainless steel, far outperforming its predecessor S30V in this regard. This gives confidence when tackling slightly more demanding tasks without fear of edge damage.

- High Corrosion Resistance: As a stainless steel, S35VN handles moisture and various environmental conditions very well, making it low-maintenance and suitable for carrying in pockets exposed to sweat or humidity.

- Reasonable Sharpenability: Compared to some of the super steels, S35VN is relatively forgiving to sharpen. While it requires quality sharpening equipment, it’s not overly frustrating to bring back to a razor edge, making it manageable for the average enthusiast.

This harmonious blend of attributes means S35VN excels in a wide array of EDC scenarios, from cutting cordage and opening boxes to preparing food or tackling light utility tasks. It’s a premium performer without the finickiness or extreme cost of some ultra-high-end steels.

Other Notable Contenders and Trade-offs

While S35VN is my preferred choice, other steels deserve mention depending on specific priorities:

- Magnacut: A newer, highly acclaimed steel offering even better corrosion resistance and toughness than S35VN, with comparable edge retention. It’s quickly becoming a top-tier choice for those willing to pay a premium.

- M390/20CV/204P: Excellent all-around performers with superb edge retention and corrosion resistance, though often slightly less tough and harder to sharpen than S35VN.

- D2: A semi-stainless tool steel known for its fantastic edge retention and toughness for its price point, though it requires more diligent maintenance due to lower corrosion resistance.

- VG-10: A solid mid-range stainless steel offering good balance, often found in Japanese-made knives.

Beyond the Steel: Maintenance and Personal Preference

Ultimately, even the best blade steel needs proper care. Regular cleaning, occasional oiling, and timely sharpening are crucial to maximizing the performance and longevity of any knife, regardless of its steel type. The “best” steel also depends heavily on individual use. If you’re constantly cutting abrasive materials, you might prioritize ultimate edge retention. If your knife sees heavy prying, toughness might be paramount. However, for a general-purpose EDC knife that needs to perform reliably in diverse daily situations, CPM-S35VN hits a sweet spot that few others can match.

By understanding the characteristics and trade-offs, you can make an informed decision that ensures your EDC companion is truly up to any task you throw its way.