When selecting a new multi-tool, what specific blade material (e.g., stainless steel, carbon steel, ceramic) do you prioritize for its balance of edge retention and corrosion resistance, and why?

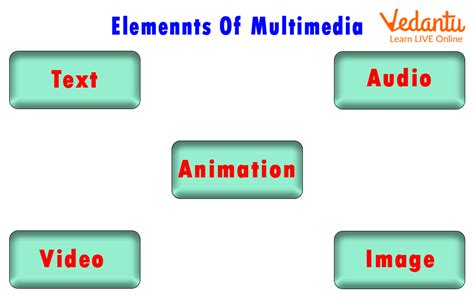

The Crucial Choice: Multi-Tool Blade Materials

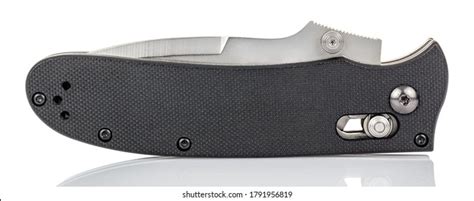

A multi-tool is a cornerstone of utility, an indispensable companion for countless tasks, from everyday fixes to outdoor adventures. While the array of tools it houses is impressive, the primary blade often sees the most use and is subjected to the most varied conditions. Therefore, the material of this blade is not just a detail; it’s a critical factor dictating its performance, longevity, and ultimately, your satisfaction. The perennial debate revolves around striking the perfect balance between a blade’s ability to hold a sharp edge and its resistance to rust and degradation. Let’s delve into the contenders.

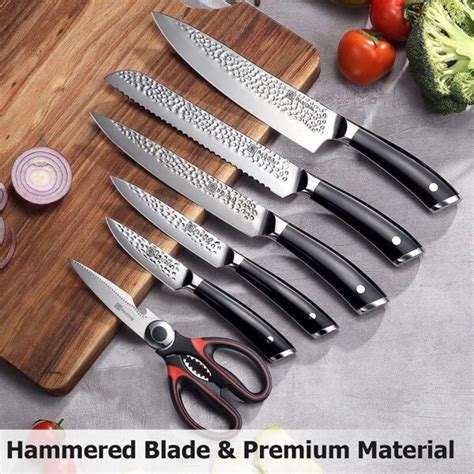

Stainless Steel: The Versatile Workhorse

Stainless steel is arguably the most common material for multi-tool blades, and for good reason. It’s an alloy with a minimum of 10.5% chromium, which forms a passive layer that resists rust and corrosion. This is a significant advantage for a tool that might be exposed to moisture, sweat, or even various chemicals without immediate cleaning. For multi-tools, especially those carried daily or used in diverse environments, its low-maintenance nature is invaluable.

However, not all stainless steels are created equal. Basic stainless steels (like 420HC) offer excellent corrosion resistance but can struggle with edge retention, requiring more frequent sharpening. Higher-end stainless steels (e.g., 154CM, S30V, or even D2 which, while technically a tool steel, is often treated as semi-stainless due to its chromium content) significantly improve edge retention while maintaining good to excellent corrosion resistance. These premium alloys achieve a much better balance, though they can be harder to sharpen.

Carbon Steel: The Sharpening Champion

Carbon steel blades (such as 1095) are renowned for their exceptional edge retention and ease of sharpening to a razor-sharp edge. They are generally tougher and less brittle than many stainless steels, making them excellent for heavy-duty cutting tasks where impact might be a concern. For those who prioritize a keen edge and don’t mind the upkeep, carbon steel is an attractive option.

The significant drawback, however, is its poor corrosion resistance. Carbon steel is highly susceptible to rust and patina formation if not meticulously cleaned and oiled after every use, especially when exposed to moisture or acidic substances. This level of maintenance is often impractical for a multi-tool, which is designed for convenience and quick deployment in varied, sometimes dirty, conditions.

Ceramic: The Exotic, Ultra-Sharp Edge

Ceramic blades, typically made from zirconium dioxide, represent the extreme end of edge retention. They can hold an edge for an incredibly long time, far surpassing most steels, and are completely impervious to rust and non-metallic corrosion. For precision cutting or tasks where a non-reactive blade is essential, ceramic offers unique advantages.

However, ceramic’s Achilles’ heel is its extreme brittleness. It is prone to chipping and breaking under lateral stress or impact, which is a frequent occurrence for a multi-tool’s blade. Sharpening also requires specialized diamond abrasives, making field maintenance nearly impossible for the average user. For a tool designed for rugged, unpredictable use, ceramic’s fragility makes it generally unsuitable.

My Prioritized Choice: High-Grade Stainless Steel

When selecting a new multi-tool, my priority for blade material is unequivocally a high-grade stainless steel. Specifically, I look for alloys like 154CM, S30V, or similar premium stainless steels. Here’s why:

- Balanced Performance: These steels offer a superior balance of edge retention and corrosion resistance. While they may not hold an edge quite as long as some carbon steels or ceramics, their performance is more than adequate for the diverse tasks a multi-tool faces. Crucially, they resist rust far better than carbon steel, demanding significantly less maintenance.

- Reliability and Durability: High-grade stainless steels are tough enough to withstand the varied stresses of multi-tool use without the brittleness of ceramic. They are less prone to chipping or snapping during unexpected prying or twisting motions, which can be common in emergency or improvised situations.

- Low Maintenance: The practical aspect of a multi-tool is paramount. It’s meant to be grabbed and used without hesitation, often in less-than-ideal conditions. The inherent corrosion resistance of good stainless steel means I don’t have to worry about immediate cleaning and oiling every time it gets damp or dirty, providing peace of mind and extending the tool’s lifespan.

- Ease of Sharpening: While premium stainless steels are harder than basic ones, they are still within the realm of home sharpening with common abrasives, unlike ceramic. This allows for field touch-ups or routine maintenance without specialized equipment.

For a tool designed for versatility and reliability across numerous environments, the practical advantages of a robust, low-maintenance, and adequately sharp stainless steel blade far outweigh the specialized benefits of carbon steel’s ultimate edge or ceramic’s extreme sharpness.