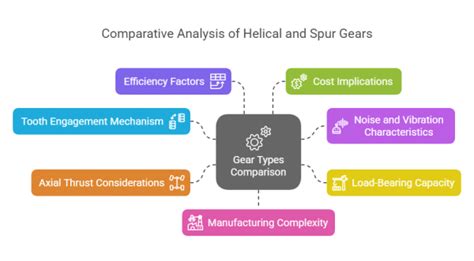

What is the primary advantage of helical gears over spur gears in terms of operation?

Understanding Gear Basics: Spur vs. Helical

Gears are fundamental components in mechanical systems, used for transmitting power and motion between rotating shafts. Among the various types, spur gears and helical gears are two of the most common, each with distinct operational characteristics. While both serve to transfer rotational energy, their tooth designs lead to significant differences in performance, particularly concerning noise, vibration, and smoothness of operation.

The Nature of Spur Gears

Spur gears are the simplest and most common type of gear. They have straight teeth cut parallel to the axis of rotation. When two spur gears mesh, the contact between the teeth occurs along the entire width of the tooth simultaneously. This abrupt, full-face contact can lead to several operational drawbacks, especially at higher speeds or under heavy loads.

- Instantaneous Engagement: Teeth engage and disengage across their full width at once.

- Noise and Vibration: The sudden impact of tooth engagement creates significant noise and vibration.

- Shock Loads: This impact can also lead to shock loads on the gear teeth and bearings.

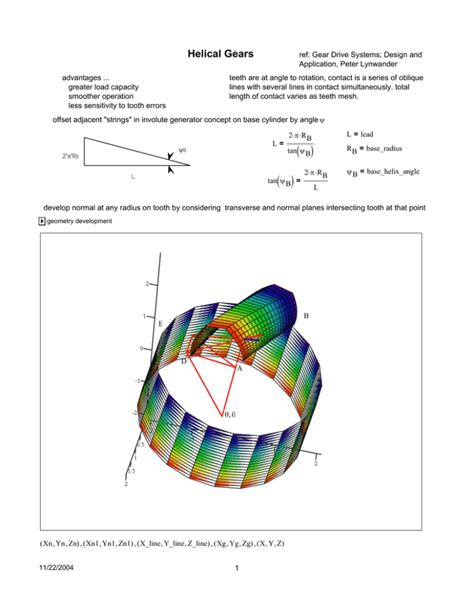

Introducing Helical Gears

In contrast, helical gears feature teeth that are cut at an angle to the gear’s axis, forming a helix. This angled design fundamentally changes how the teeth interact during meshing, providing a crucial advantage over their spur gear counterparts. Instead of engaging all at once, the contact between helical gear teeth begins at one end and progressively spreads across the tooth face as the gears rotate.

The Primary Advantage: Smooth and Quiet Operation

The primary advantage of helical gears over spur gears, in terms of operation, is their significantly smoother and quieter performance. This superior operational characteristic stems directly from their unique tooth geometry and the resulting engagement process.

Because the teeth of helical gears engage gradually, rather than abruptly, the load is transferred progressively from one tooth to the next. This progressive contact has several key benefits:

- Gradual Load Transfer: The initial contact is a point, which then expands into a line as the gears rotate. This smooth transition reduces the impact shock associated with spur gears.

- Reduced Noise: The absence of sudden impacts significantly lowers the operational noise levels, making helical gears ideal for applications where quietness is a priority.

- Less Vibration: The continuous and overlapping contact of teeth minimizes vibrations, contributing to overall system stability and longevity.

- Higher Load Capacity: Because multiple teeth are often in contact simultaneously, and the load is distributed more evenly across the tooth face, helical gears can often transmit higher loads or operate at higher speeds than spur gears of the same size.

This smoother engagement also means that helical gears experience less wear and tear on their teeth, leading to a longer operational life for the gear set and associated components. The continuous contact helps to distribute the stress more broadly, reducing localized stress concentrations.

Trade-offs and Applications

While helical gears offer substantial benefits, they are not without their considerations. The angled teeth generate an axial thrust force along the gear’s axis, which must be accommodated by thrust bearings in the system. This adds complexity and cost to the design. However, for applications demanding high speed, heavy loads, and most importantly, smooth and quiet operation – such as automotive transmissions, industrial machinery, and high-precision equipment – the advantages of helical gears far outweigh this additional design complexity.

Conclusion

In summary, while spur gears are simple and effective for many applications, the primary operational advantage of helical gears lies in their ability to provide significantly smoother and quieter power transmission. This is achieved through the gradual and continuous engagement of their angled teeth, which reduces impact, vibration, and noise. Despite the added complexity of managing axial thrust, helical gears are the preferred choice in scenarios where operational refinement and efficiency are paramount, making them a cornerstone of modern mechanical engineering.