What is the main advantage of a helical gear over a spur gear?

Understanding Spur Gears: The Baseline

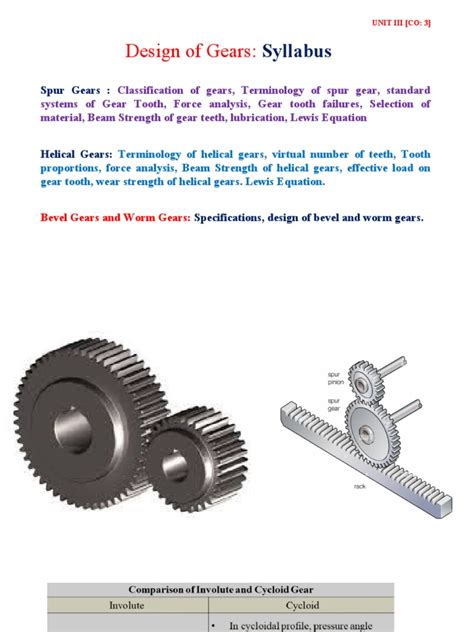

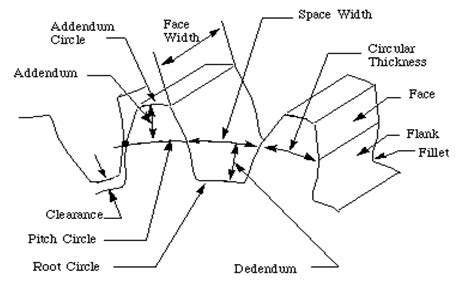

To fully appreciate the advantages of helical gears, it’s essential to first understand their more conventional counterpart: the spur gear. Spur gears are the simplest and most common type of gear, characterized by their straight teeth running parallel to the axis of rotation. When two spur gears mesh, the entire width of a tooth makes contact simultaneously. This direct, instantaneous engagement can lead to several characteristics that, while acceptable for many applications, present limitations in others.

Spur gears are known for their efficiency and ease of manufacture. They are excellent for transmitting power between parallel shafts and are widely used in applications where noise and vibration are not critical concerns, such as in simple machinery, clocks, and some types of pumps. However, the sudden impact of tooth-on-tooth contact can generate significant noise, vibration, and shock loads, especially at higher speeds or under heavy loads.

The Helical Gear: A Design Evolution

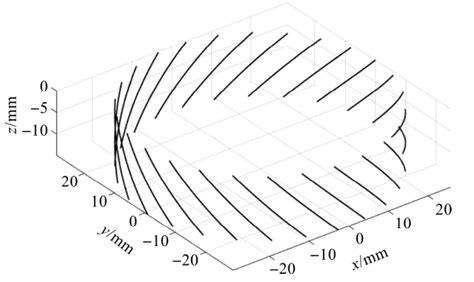

Helical gears represent an evolution in gear design, specifically engineered to overcome some of the inherent limitations of spur gears. The distinguishing feature of a helical gear is its teeth, which are cut at an angle (or helix) to the gear’s axis of rotation, rather than parallel to it. This angled design fundamentally changes how the teeth engage and disengage, leading to a host of performance benefits.

The Main Advantage: Smoother, Quieter, and Stronger Engagement

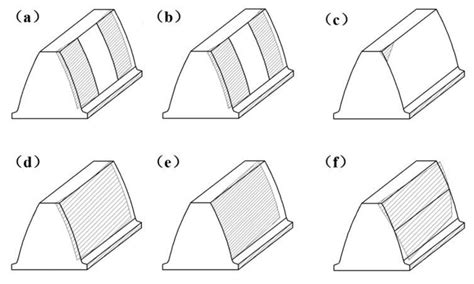

The principal advantage of a helical gear over a spur gear is its ability to provide significantly smoother, quieter operation, and increased load-carrying capacity. This crucial benefit stems directly from the helical angle of its teeth. When two helical gears mesh, the contact begins at one end of a tooth and gradually progresses along the tooth’s face as the gears rotate, until the contact point reaches the other end. This ‘rolling’ or ‘gradual’ engagement contrasts sharply with the ‘full-face’ engagement of spur gears.

Benefits of Gradual Engagement:

-

Reduced Noise and Vibration: The gradual transfer of load from one tooth to the next eliminates the sudden impact associated with spur gears. This results in a much smoother transition of power, significantly reducing noise and vibration, making helical gears ideal for applications requiring quiet operation, such as automotive transmissions and machine tools.

-

Higher Load Capacity: At any given moment, more than one pair of teeth can be in contact in a helical gear set, sharing the load more effectively. This distributed load, coupled with the extended contact area, allows helical gears to transmit higher torques and handle greater shock loads compared to spur gears of the same size and material.

-

Increased Durability and Lifespan: Reduced shock loading and smoother power transmission minimize wear and tear on the gear teeth and other components in the system, leading to greater durability and a longer operational lifespan.

-

Suitability for High-Speed Applications: The inherent smoothness of helical gear operation makes them well-suited for high-speed applications where spur gears would generate excessive noise and vibration, potentially leading to operational failure.

Trade-offs and Considerations

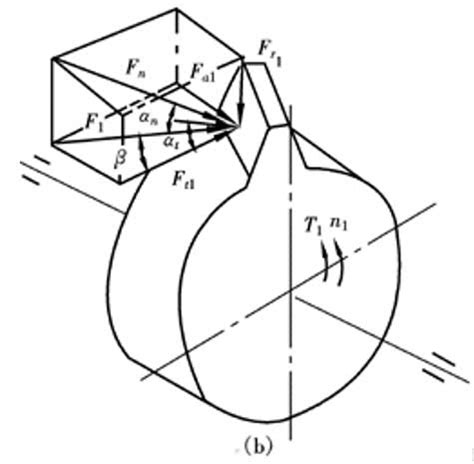

While the advantages are significant, it’s important to note that helical gears do present some trade-offs. The angled teeth generate an axial thrust force along the gear’s axis. This thrust must be accommodated by thrust bearings, which adds complexity and cost to the system. Double helical or herringbone gears can be used to cancel out this axial thrust by having two helical sections with opposite helix angles. Furthermore, the manufacturing of helical gears is generally more complex and therefore more expensive than that of spur gears.

Conclusion

In summary, the main advantage of a helical gear over a spur gear is its ability to deliver superior performance in terms of smoothness, quietness, and load capacity. This is directly attributable to the gradual, continuous engagement of its angled teeth, which distributes the load more evenly and eliminates the sudden impact associated with spur gears. Despite their higher manufacturing cost and the need to manage axial thrust, helical gears are the preferred choice for demanding applications where efficiency, reduced noise, and reliability are paramount, making them a cornerstone of modern mechanical engineering.