What is the pitch diameter of a spur gear with 40 teeth and a module of 2.5 mm?

Learn how to easily calculate the pitch diameter of a spur gear using its module and number of teeth with a straightforward formula.

Learn how to easily calculate the pitch diameter of a spur gear using its module and number of teeth with a straightforward formula.

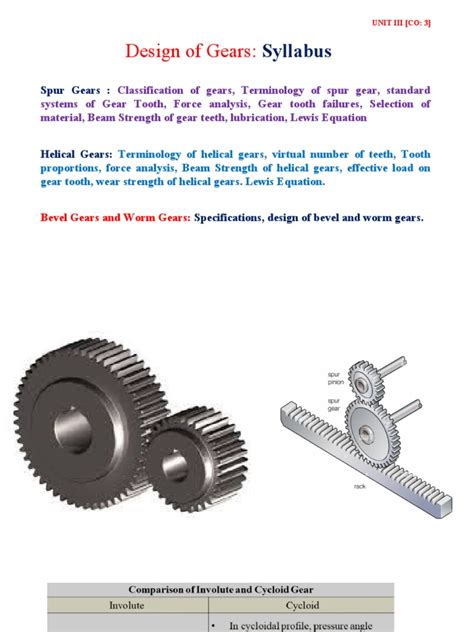

The primary advantage of a helical gear over a spur gear lies in its ability to provide smoother, quieter operation and higher load capacity due to its angled teeth and gradual tooth engagement.

The primary factor limiting the efficient high-speed operation of a spur gear without excessive noise or wear is the dynamic tooth load and resulting vibrations caused by manufacturing inaccuracies and elastic deformation during meshing.

In high-speed, high-load applications, helical gears offer smoother, quieter operation and higher load capacity compared to spur gears, but introduce axial thrust and higher manufacturing costs.

The primary advantage of a helical gear over a spur gear in power transmission is its angled teeth, which enable smoother, quieter operation and reduced shock loads due to gradual tooth engagement.

The primary advantage of a helical gear over a spur gear in power transmission is its significantly smoother and quieter operation due to the gradual, continuous engagement of its angled teeth, leading to reduced vibration and increased load capacity.