What is the primary advantage of a helical gear over a spur gear in power transmission?

When it comes to mechanical power transmission, gears are fundamental components. Two of the most common types are spur gears and helical gears, each with distinct characteristics that make them suitable for different applications. While both serve to transfer rotational motion and torque, helical gears offer a significant advantage over spur gears, particularly in demanding scenarios.

Understanding Spur Gears: The Basics

Spur gears are perhaps the simplest and most common type of gear. They have straight teeth that are cut parallel to the axis of rotation. When two spur gears mesh, the contact between their teeth occurs along the entire face width simultaneously. This sudden, full-line contact is effective for many applications but has a notable drawback.

This simultaneous engagement can lead to a sudden impact load, generating considerable noise and vibration, especially at higher speeds or under heavy loads. While robust and easy to manufacture, their operation can be rougher compared to other gear types, limiting their use in applications requiring high precision or quiet operation.

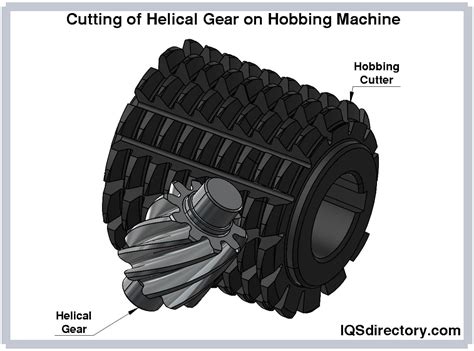

The Helical Gear Difference: Angled Engagement

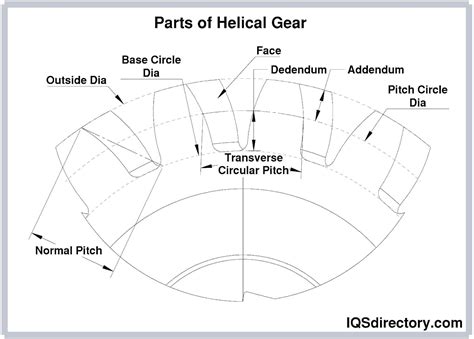

In contrast, helical gears feature teeth that are cut at an angle (helix angle) to the gear’s axis of rotation, rather than parallel. This angular design is the key to their superior performance. When two helical gears mesh, the contact between their teeth is not instantaneous across the entire face width. Instead, engagement begins at one end of the tooth and progresses gradually along the tooth face as the gears rotate.

The Primary Advantage: Smooth, Quiet Operation

The gradual engagement of helical gear teeth is their most significant advantage. This progressive contact means that the load is transferred smoothly from one tooth pair to the next. Unlike the abrupt engagement of spur gears, helical gears provide a continuous, rolling contact. This leads directly to several crucial benefits:

- Reduced Noise: The gradual engagement significantly minimizes the impact shock, resulting in much quieter operation. This is paramount in applications where noise reduction is critical, such as automotive transmissions or industrial machinery in human-occupied environments.

- Less Vibration: The smooth transfer of power reduces mechanical vibrations, which can extend the lifespan of not only the gears themselves but also associated components like bearings and shafts.

- Lower Dynamic Loads: Because the load is applied more gradually, the dynamic stresses on the gear teeth are substantially lower. This reduces wear and fatigue, leading to greater reliability and durability.

Beyond Smoothness: Enhanced Performance

While quiet and smooth operation is the primary benefit, the design of helical gears also allows for other performance advantages:

- Higher Load Carrying Capacity: Due to the gradual engagement and the fact that more than one tooth can be in contact at any given time (depending on the helix angle and face width), helical gears can typically carry higher loads than spur gears of the same size. The load is distributed over a larger contact area.

- Suitable for High Speeds: The reduced impact and vibration make helical gears ideal for high-speed applications where spur gears would generate excessive noise and heat.

- Increased Efficiency: The smoother meshing often translates to slightly higher efficiency, as less energy is lost to vibration and noise.

A Consideration: Axial Thrust

It’s important to note that the angled teeth of helical gears introduce an axial thrust force along the gear’s axis, which is not present in spur gears. This axial thrust must be accounted for in bearing design, often requiring the use of thrust bearings to handle the force. This is one of the main complexities of helical gear systems compared to spur gears.

Conclusion

In summary, the primary advantage of a helical gear over a spur gear in power transmission is its ability to provide significantly smoother, quieter operation and reduced vibration. This stems directly from its angled teeth, which allow for gradual, progressive engagement rather than instantaneous full-face contact. While spur gears remain valuable for simple, low-speed, or cost-sensitive applications, helical gears are the preferred choice for systems demanding high speeds, heavy loads, and a quiet, efficient, and reliable power transfer.