What does ‘addendum modification’ achieve in a gear design, and when is it typically applied?

In the intricate world of mechanical engineering, gears are fundamental components, transferring power and motion with precision. However, standard gear tooth profiles can sometimes suffer from issues like undercut, especially when designing gears with a low number of teeth. This is where ‘addendum modification’ emerges as a vital design technique, allowing engineers to fine-tune gear geometry for optimal performance and longevity.

Understanding Addendum Modification

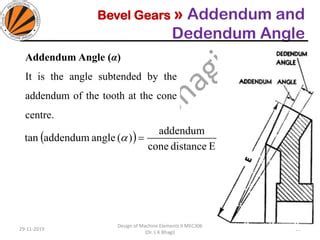

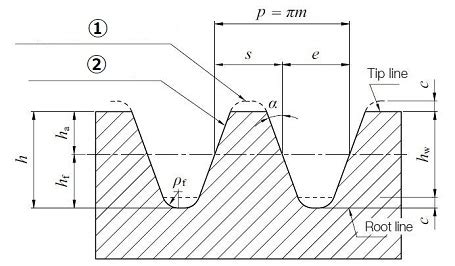

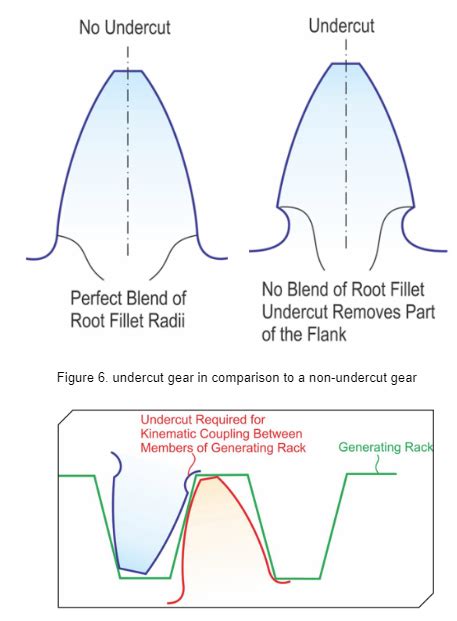

Addendum modification, also known as profile shifting or tooth correction, is a process where the tooth profile of a gear is adjusted from its standard involute form. This adjustment is achieved by shifting the generating rack (or cutter) radially outwards or inwards during the gear cutting process, without changing the number of teeth or the basic pitch circle diameter. The amount of modification is typically expressed as a coefficient, ‘x’, multiplied by the module.

What Does It Achieve? Key Benefits

The application of addendum modification serves several critical purposes in gear design, directly impacting the performance, reliability, and lifespan of a gear set:

- Preventing Undercut: This is arguably the most common and significant reason for addendum modification. When gears have a small number of teeth (below the minimum for a standard involute profile, often around 17 teeth for a 20-degree pressure angle), the generating hob can “undercut” the base of the tooth, weakening it and reducing the active involute profile. Positive addendum modification shifts material outwards, effectively preventing this detrimental phenomenon.

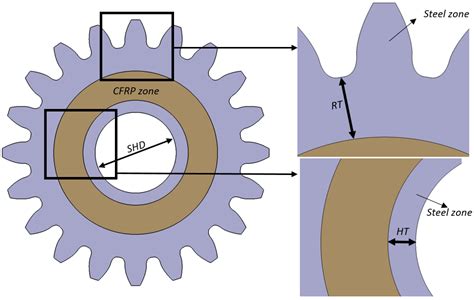

- Increasing Tooth Strength: Positive modification makes the tooth broader at its root, significantly increasing its bending fatigue strength. This is particularly beneficial for pinions, which often experience higher stress cycles than their mating gears due to their smaller number of teeth.

- Optimizing Contact Conditions and Contact Ratio: By adjusting the tooth profile, engineers can optimize the meshing action. Modification can influence the length of the path of contact, which in turn affects the contact ratio. A higher contact ratio generally leads to smoother operation, reduced noise, and increased load-carrying capacity.

- Balancing Wear Between Mating Gears: In a gear pair, the pinion often undergoes more stress cycles and thus tends to wear out faster. Applying a positive modification to the pinion and a negative (or smaller positive) modification to the gear can help balance the load distribution and wear rate between the two components, extending the life of the gear set.

- Adjusting Center Distance: Addendum modification can be used to achieve a specific operating center distance for a gear pair without changing the gear ratio or using non-standard cutters. This is particularly useful when designing replacement gears or fitting gears into existing housings.

- Reducing Noise and Vibration: Optimized tooth profiles can lead to smoother engagement and disengagement, reducing impact loads, which in turn diminishes noise and vibration during operation.

When Is Addendum Modification Typically Applied?

The decision to apply addendum modification is driven by several design and operational factors:

- Gears with a Low Number of Teeth: As mentioned, pinions with a small tooth count are highly susceptible to undercut. Positive addendum modification is almost mandatory in such cases to ensure proper tooth geometry and strength.

- High Load and High-Performance Applications: In machinery where gears transmit significant power or operate under extreme conditions (e.g., automotive transmissions, heavy industrial machinery), modifying the addendum enhances tooth strength and load distribution, preventing premature failure.

- Specific Center Distance Requirements: When a gear set needs to operate at a precise center distance that cannot be achieved with standard gears and standard tooth counts, addendum modification provides the flexibility to meet these geometric constraints while maintaining the desired gear ratio.

- Minimizing Size and Weight: By strengthening the teeth through modification, it’s sometimes possible to design smaller gears for a given load, contributing to more compact and lighter assemblies.

- Optimizing Gear Mesh Performance: For applications demanding very high precision, low noise, or specific contact characteristics, engineers meticulously calculate and apply addendum modification to fine-tune the engagement process.

- Interchangeability and Replacement Parts: When designing replacement gears for existing equipment, addendum modification might be used to match the operating characteristics and center distance of the original components, even if the original design was not modified.

Types of Modification: Positive vs. Negative

Addendum modification can be positive or negative:

- Positive Modification (x > 0): The cutter is shifted outwards from the gear blank’s center. This increases the addendum, decreases the dedendum, and thickens the tooth at the base. It prevents undercut, increases tooth strength, and typically increases the pressure angle in the mesh.

- Negative Modification (x < 0): The cutter is shifted inwards. This decreases the addendum, increases the dedendum, and thins the tooth at the base. Negative modification is less common for pinions due to the risk of undercut but can be applied to the larger mating gear in a pair to balance wear or achieve specific center distances.

It’s important to note that when a gear pair is modified, the sum of the modification coefficients (x1 + x2) significantly influences the resulting operating pressure angle and center distance. Careful calculation is essential to ensure the desired outcome without introducing new problems like excessive backlash or point contact.

Considerations and Challenges

While highly beneficial, addendum modification is not without its complexities. It directly influences other gear parameters such as the operating pressure angle, backlash, and the contact ratio. Incorrect application can lead to reduced contact strength, increased wear, or even interference. Therefore, the design process often involves iterative calculations and specialized software to achieve the optimal modification for a given application.

Conclusion

Addendum modification is a sophisticated yet indispensable technique in modern gear design. By subtly altering the tooth profile, engineers gain powerful control over fundamental gear characteristics – preventing undercut, enhancing strength, balancing wear, and fine-tuning operating parameters. Its judicious application allows for the creation of more robust, efficient, and quieter gear systems, ensuring their reliable performance across a vast spectrum of industrial and mechanical applications.