What is the primary factor limiting the speed at which a spur gear can operate efficiently without excessive noise or wear?

Understanding High-Speed Spur Gear Limitations

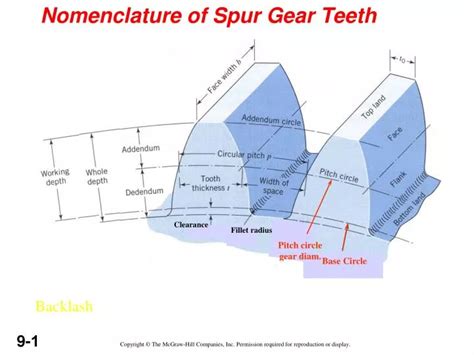

Spur gears are fundamental mechanical components, widely used for transmitting power and motion between parallel shafts. While their simplicity makes them robust for many applications, their ability to operate at high speeds efficiently and quietly is not unlimited. As operating speeds increase, several factors become critical, but one stands out as the primary limiter: dynamic tooth loads and the subsequent vibrations they induce.

The Dominance of Dynamic Tooth Loads and Vibrations

At low speeds, the forces acting on gear teeth are predominantly static, determined by the transmitted torque. However, as speed increases, inertial forces, elastic deformation, and microscopic manufacturing inaccuracies interact to create significant dynamic forces that can far exceed the static loads. These dynamic loads cause the teeth to accelerate and decelerate rapidly during engagement and disengagement, leading to impacts, vibrations, and noise.

Sources of Dynamic Loading

Several underlying issues contribute to these detrimental dynamic loads:

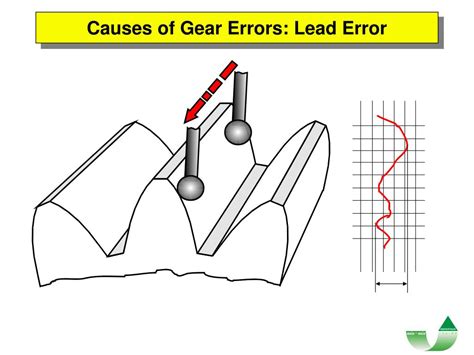

- Manufacturing Inaccuracies: Even the most precisely manufactured gears have minute errors in tooth profile, pitch, and runout. At low speeds, these imperfections might be absorbed by the elasticity of the teeth. At high speeds, however, they cause the teeth to engage prematurely or late, resulting in an impact. This impact generates a sudden surge in load, creating noise and accelerating wear.

- Elastic Deformation and Tooth Deflection: Under load, gear teeth will elastically deform. At high speeds, the time available for this deformation to occur and recover is greatly reduced. If one tooth deflects more than its predecessor or successor, it can lead to an uneven load distribution or a momentary loss of contact followed by a forceful re-engagement, inducing impact loads.

- Lubrication Film Instability and Breakdown: A critical aspect of gear operation is the hydrodynamic lubrication film that separates the tooth surfaces. At high speeds, maintaining this film can be challenging. Dynamic impacts can momentarily break through the lubricant film, leading to metal-to-metal contact, increased friction, and localized heating. This directly contributes to wear and noise.

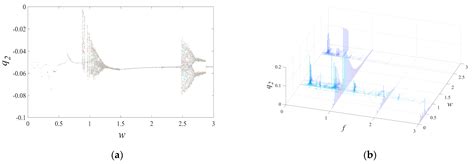

- Resonance and System Vibrations: If the operating speed of the gear train coincides with the natural frequencies of the gears, shafts, or the entire machine structure, resonance can occur. This amplifies vibrations, leading to excessive noise and potentially catastrophic failure.

Consequences of Excessive Dynamic Loads

The high dynamic loads and vibrations manifest in several undesirable ways:

- Increased Noise Generation: The most immediate and noticeable consequence is noise. Rapid tooth impacts and the vibration of the gear body and surrounding structure generate audible sound waves, which can range from a hum to a piercing shriek.

- Accelerated Wear and Pitting: Metal-to-metal contact due to lubrication breakdown, combined with high impact stresses, leads to accelerated surface wear, pitting, and even scuffing. This reduces the gear’s lifespan and can lead to premature failure.

- Reduced Operational Efficiency: Energy is lost in generating noise and heat from friction and impacts. This reduces the overall mechanical efficiency of the gear train, meaning more input power is required for the same output.

- Risk of Component Failure: Repeated high dynamic stresses can lead to fatigue cracks in gear teeth, ultimately causing tooth breakage and catastrophic failure of the gear system.

Mitigating High-Speed Challenges

Addressing these dynamic limitations involves a multi-faceted approach. High-precision manufacturing and rigorous quality control minimize initial errors. Tooth modifications, such as profile crowning or tip relief, are often employed to accommodate elastic deformation and ensure smoother engagement. Advanced lubrication systems and high-performance lubricants are crucial for maintaining the separating film. Furthermore, careful material selection and heat treatment enhance tooth strength and fatigue resistance, while system-level dampening and vibration analysis help avoid resonance.

Conclusion

In summary, while factors like material strength, lubrication, and static load capacity are important, the primary constraint on a spur gear’s efficient high-speed operation without excessive noise or wear is the complex interplay of dynamic tooth loads and the resulting vibrations. These dynamic effects are exacerbated by manufacturing imperfections, elastic deformations, and the challenges of maintaining a stable lubrication film at increased speeds. Understanding and mitigating these dynamic phenomena are key to designing high-performance, durable, and quiet spur gear systems for demanding applications.