How does a gear ratio impact the speed and torque output of a mechanical system?

In the realm of mechanical engineering, gear ratios are fundamental in dictating how power is transmitted and transformed within a system. They are the unsung heroes that allow engines to drive heavy machinery, bicycles to climb steep hills, and cars to reach high speeds. Understanding the intricate relationship between a gear ratio and the resulting speed and torque output is crucial for designing and optimizing any mechanical system.

What is a Gear Ratio?

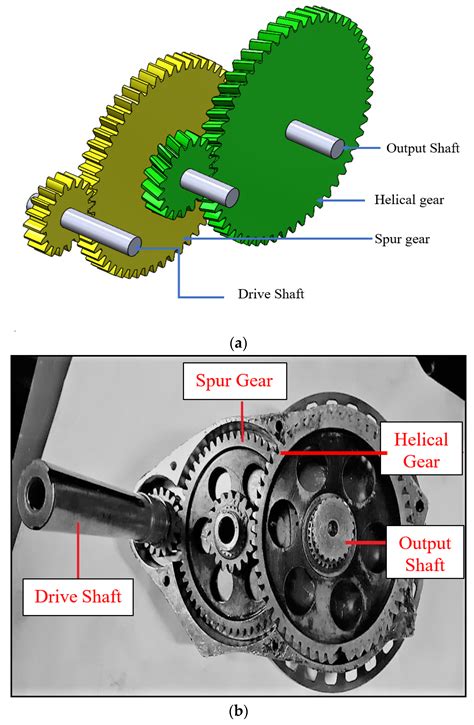

A gear ratio is simply the ratio of the number of teeth on the driven gear (output) to the number of teeth on the driving gear (input). Alternatively, it can be expressed as the ratio of the input speed to the output speed, or the output torque to the input torque. This ratio determines how much the input rotational speed is increased or decreased, and conversely, how much the input torque is multiplied or divided at the output.

Impact on Rotational Speed

The primary effect of a gear ratio on a mechanical system is the alteration of rotational speed. There are two main scenarios:

- Speed Reduction (Torque Multiplication): When the driven gear has more teeth than the driving gear, the output shaft will rotate slower than the input shaft. For instance, if the driving gear has 10 teeth and the driven gear has 20 teeth, the gear ratio is 20:10 or 2:1. This means the output shaft will rotate at half the speed of the input shaft. This setup is commonly used in applications requiring high torque and lower speed, such as in the lower gears of a car or industrial conveyor belts.

- Speed Increase (Torque Reduction): Conversely, if the driven gear has fewer teeth than the driving gear, the output shaft will rotate faster than the input shaft. For example, a driving gear with 20 teeth and a driven gear with 10 teeth results in a 10:20 or 1:2 gear ratio. Here, the output shaft spins at twice the speed of the input shaft. This is often seen in overdrive gears in vehicles or bicycle chainrings where high speed is desired at the expense of torque.

Impact on Torque Output

The impact on torque is inversely proportional to the impact on speed, assuming no energy losses (100% efficiency). This relationship stems from the principle of conservation of energy: what you gain in speed, you lose in torque, and vice-versa.

- Higher Torque, Lower Speed: In a speed-reduction scenario (e.g., 2:1 gear ratio), the output shaft experiences a multiplication of torque. If the input torque is 10 Nm, the output torque would ideally be 20 Nm (2 x 10 Nm), neglecting friction and other losses. This is why lower gears in vehicles provide more pulling power.

- Lower Torque, Higher Speed: In a speed-increase scenario (e.g., 1:2 gear ratio), the output torque is divided. If the input torque is 10 Nm, the output torque would ideally be 5 Nm (1/2 x 10 Nm). This setup prioritizes speed over raw turning force.

The Power-Speed-Torque Relationship

The underlying principle governing this inverse relationship between speed and torque is the conservation of mechanical power. Power (P) is the product of torque (T) and angular velocity (ω): P = T × ω. In an ideal mechanical system, the input power equals the output power. Therefore, if the gear ratio reduces the angular velocity (speed) by a certain factor, the torque must increase by the same factor to maintain constant power, and vice-versa.

In real-world systems, efficiency losses due to friction, heat, and other factors mean that output power is always slightly less than input power. However, the fundamental trade-off between speed and torque governed by the gear ratio remains. Engineers meticulously calculate and select appropriate gear ratios to match the load requirements and desired performance characteristics of a mechanical system.

Practical Applications of Gear Ratios

Gear ratios are ubiquitous in modern technology:

- Automobiles: Transmissions use multiple gear ratios to allow the engine to operate efficiently across a wide range of vehicle speeds, providing high torque for acceleration and low torque for cruising.

- Bicycles: Derailleur systems allow riders to change gear ratios to optimize effort for climbing hills (high torque, low speed) or riding on flat terrain (low torque, high speed).

- Wind Turbines: Gearboxes within wind turbines convert the slow, high-torque rotation of the blades into the high-speed, lower-torque rotation required by the electrical generator.

- Industrial Machinery: Robotics, conveyor systems, and manufacturing equipment all rely on precise gear ratios to deliver specific speeds and torques for their operational tasks.

Conclusion

Gear ratios are far more than just a component in a mechanical system; they are the strategic elements that enable the conversion and optimization of power, speed, and torque. By carefully selecting the number of teeth on interacting gears, engineers can precisely control the output characteristics to meet specific performance requirements. Whether it’s for raw power, blistering speed, or a balance of both, the gear ratio stands as a testament to elegant mechanical design, influencing virtually every machine that moves, lifts, or spins.